Varieties of furniture bolts, its classification and applications

A bolt is a type of mounting hardware. It is a pin with a uniformly applied thread, on one end of which is a hex head. In practice, a furniture bolt provides reliable fastening of two products to each other. For better grip, screw the nut onto the end of the pin without a cap.

Content

Classification

Bolts designed to secure various links can be divided into several categories.

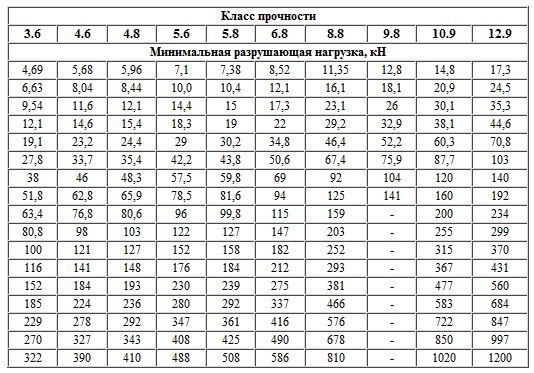

Strength class

The strength of the pins directly depends on the material and manufacturing technology. About 95% of the manufactured bolts were cast from steel. Depending on the strength category, various types of steel are used and one or another heat treatment technology is used.

Each discharge has its own digital designation. A total of 11 classes are distinguished. Furniture bolts have the following classes: 3.6, 4.6, 4.8, 5.6, 5.8 and 8.8. Strength characteristics of all classes are spelled out in all details in GOST and in international ISO standards.

The lowest class is for wood products with little responsibility in the joints. Their composition is 100% classical steel without any additives and is not subjected to special heat treatment.

Pins having a medium strength class are used most often. When they are created, alloy steel is used, in the composition of which there is carbon in an amount of not more than 0.4%.

Couplings, like pins, have discharges of strength. When making a coupler, it is necessary to check the strength of the nut and the pin for compliance. With the right numbers, the best strength is achieved.

The form

For each type of production, fixtures of a certain shape are made:

- Classic - the screw head is made in the form of a hexagon, and at the end of the shaft there is a thread with which several parts coupled with the coupling are easily and reliably coupled;

- Flanged - the base of such mounting components has a rounded "skirt", which is needed to replace nuts and washers;

- Hinged - has a complex shape: there is a hole in the place of the hat. The rest of the pin looks like a classic pattern: the ending is covered with thread;

- Anchor - with their help, a through connection of various links is performed. Due to the special strength, anchors are used for screeding in places requiring increased responsibility;

- Eye-bolts - in place of a standard hat they have a loop. Such pins can withstand a large load, because they uniformly disperse it over the entire surface of the part.

The strength and reliability of pulling together parts directly depends on the shape of the fasteners.

Scope of application

Initially, pieces of furniture were connected to each other by means of dowels and wedges of a certain type. With the development of technology, screed methods have been improved. As a result, special metal rods were created. Currently, they are used to assemble various furniture, namely to connect components:

- Tables and chairs;

- Armchair and sofas;

- Beds

- Dressers and nightstands;

- Cabinets and walls;

- Kitchen sets.

Furniture pins are widespread in various areas of production due to their strength. Very often they are used in construction and repair to connect wooden parts. For example, it can be stairs or small wooden structures such as arbors.

Along with this, pins are used to tighten parts during the construction of bridges. Roadworks are not complete without such screws.

In addition, furniture pins are used in mechanical engineering to connect parts in the case when the height of the cap should be minimal. Also, pins can be found in everyday life as connecting elements of various kinds of mechanical devices, for example, in door locks.

Varieties

All types of furniture fasteners are divided into several types.

Threaded

A set of a threaded pin on one side and nuts of suitable strength are used when joining parts of beds, sofas, cabinet furniture, chairs and tables.

The appearance and design of the threaded rod differs significantly from similar parts intended for general use. This requires the specifics of furniture manufacturing. Fasteners must meet the requirements of not only strength, but also aesthetics. Furniture is a component of the interior and it should look perfect, so the bolts should be practically invisible at the end of assembly.

The threaded bolt has several varieties, the most popular of which is a hardware with a driven nut. No less metric screws are used in the production, which are complemented by elongated couplings.

The advantage of threaded fasteners is high reliability. As for the installation, it is not simple. Before screwing the threaded dowel, it is necessary to make preliminary holes, which must be measured with high accuracy. Incorrect marking can greatly affect the assembly process.

Confirmate

For greater convenience and ease of use, pins of a new design were created. They are made according to the type of screws. Confirmates, they are also called Euro-screws, belong to screw-type couplers. By design and principle of operation, they are similar to screws and self-tapping screws.

The main advantage of confirmation is the speed of assembly. The drawback of the Euroscrew is the fact that the outer part is not hidden from prying eyes, and this is not very convenient in the manufacture of some types of furniture.

Eccentric screed

The most popular, especially among expensive and high-quality furniture, is the "invisible" mount. The construction of the screed consists of an eccentric and a separate foot, which fixes the eccentric, firmly securing in a blind hole.

In addition to modern and very convenient fastener options, classic but slightly outdated products are used. These include screws with corners and wooden dowels.

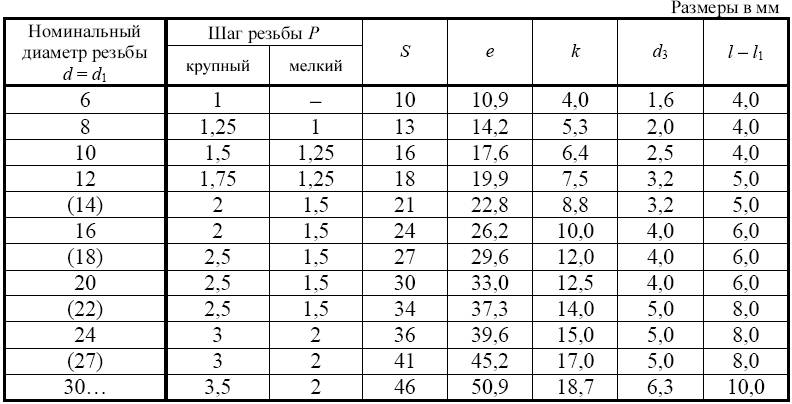

Characteristics and Sizes

The high load on the joints requires high reliability so that the fabricated structure does not break apart in parts. To prevent this from happening, it is necessary to use high-strength materials when creating fasteners. The most suitable at present is carbon steel. Value for money for this metal is the most optimal.

If the screed does not require a heavy load, then we can use less durable hardware made of brass, steel of class A2, A4 and polyamide. Such materials are of medium strength and corrosion resistant. A4 is immune to acidic substances.The price of rods made of such materials is much higher than for rods coated with zinc or consisting of ordinary steel. The appearance of the pins made of zinc is much more aesthetic than others.

The coating for fasteners made of carbon steel may vary slightly. For different hardware use their spraying. In the first case - “white” zinc, in the second - “yellow”. In addition to the external difference, yellow zinc has an internal one: an additional layer of protection, which increases the service life of the product.

Standard options

Table with specifications and dimensions.

| d1 | M5 | M6 | M8 | M10 | M12 | M16 | M20 | |

| R | 0,8 | 1 | 1,25 | 1,5 | 1,75 | 2 | 2,5 | |

| d2 | 13,5 | 16,55 | 20,65 | 24,65 | 30,65 | 38,8 | 46,8 | |

| k | 3,3 | 3,88 | 4,88 | 5,38 | 6,95 | 8,95 | 11,05 | |

| f | 4,1 | 4,6 | 5,6 | 6,6 | 8,75 | 12,9 | 15,9 | |

| V | 5,48 | 6,48 | 8,58 | 10,58 | 12,7 | 16,7 | 20,84 | |

| b | L ≤ 125 | 16 | 18 | 22 | 26 | 30 | 38 | 46 |

125 | 22 |

24 |

28 |

32 |

36 |

44 |

52 |

| |

| L> 200 | 41 | 45 | 49 | 57 | 65 | |||

| L | Weight 1000 pcs. bolts in kg | |||||||

| 16 | 4 | 6.9 | ||||||

| 20 | 4,5 | 7,6 | 13,8 | 22,7 | ||||

| 25 | 5,1 | 8,5 | 15,4 | 25,2 | ||||

| 30 | 5,9 | 9,6 | 17 | 27,7 | 45,7 | |||

| 35 | 6,7 | 10,7 | 19 | 30,2 | 49,4 | |||

| 40 | 7,5 | 11,8 | 21 | 32,7 | 53,1 | |||

| 45 | 8,3 | 12,9 | 23 | 35,8 | 56,8 | |||

| 50 | 9,1 | 14 | 25 | 38,9 | 61,2 | 119 | ||

| 55 | 9,9 | 15,1 | 26,9 | 42 | 65,6 | 126 | ||

| 60 | 10,7 | 16,2 | 28,9 | 45,1 | 70 | 133 | ||

| 65 | 11,5 | 17,3 | 30,9 | 48,2 | 74,4 | 141 | ||

| 70 | 12,3 | 18,4 | 32,9 | 51,3 | 78,8 | 149 | 247 | |

| 80 | 13,9 | 20,6 | 36,8 | 57,5 | 87 | 165 | 272 | |

| 90 | 22,8 | 40,8 | 63,7 | 96 | 181 | 297 | ||

| 100 | 25 | 44,8 | 69,9 | 105 | 197 | 322 | ||

| 110 | 27,2 | 48,8 | 76,1 | 114 | 213 | 347 | ||

| 120 | 29,4 | 52,8 | 82,3 | 123 | 229 | 372 | ||

| 130 | 31,6 | 56,8 | 88,5 | 132 | 245 | 397 | ||

| 140 | 32,8 | 60,8 | 95 | 141 | 261 | 422 | ||

| 150 | 35 | 64,8 | 101 | 150 | 277 | 447 | ||

| 160 | 107 | 159 | 293 | 497 | ||||

| 180 | 119 | 177 | 325 | 547 | ||||

| 200 | 131 | 195 | 357 | 597 | ||||

Conventional signs:

d1 is the nominal diameter of the thread;

P is the distance between adjacent thread points;

d2 is the diameter of the cap;

k is the height of the hat;

f - head height, not less;

V is the side size of the square heading;

b is the length of the thread;

L is the length of the product.

Selection tips

Which manufacturer to purchase screws for screed furniture, each buyer decides for himself. The domestic market is replete with a number of different manufacturers, most of which produce fasteners of the highest quality that meet all the requirements of the state standard.

When purchasing products for furniture assembly, it is necessary to check with the supplier for certificates that confirm its quality. To exclude the purchase of low-quality hardware, it is recommended to contact only large companies whose activities are confirmed by relevant documents and authorities. Reputation for large manufacturers is very important, therefore it is almost impossible to purchase defective products from them.

Particular attention should be paid to the external signs of the fasteners, because it is unacceptable to use bolts with a curve and heterogeneous thread during fastening. The presence of cracks, chips and other defects will interfere with high-quality assembly and cause rapid deterioration of the product.

If the description of the part states that it is not subject to corrosion, then it should look perfect, not just be painted with silver paint, but coated with a protective layer using special technology. You can check it yourself, just twist the pin in your hands and scrape it a little, if there are no traces on your hands, then there is a high probability of high-quality coating.

Check the quality of the plug as follows:

- Pick a regular key that fits the size;

- Pick up a nut;

- Try to screw a nut on a hardware.

If the process of winding up the coupling goes smoothly, you can be sure of the right part.

To verify the quality and reliability of the assembly element until it is used for its intended purpose is 100% impossible. For greater reliability and convenience, fasteners should be purchased by professionals for whom such a choice does not cause difficulties.

Video