Features of an eccentric furniture screed, installation rules

In the manufacture of furniture, different types of fasteners are used, which ensure the reliability and durability of the structure. The most common lately has become a furniture eccentric screed. It is also known under the names "minifix" or "rasteks". The eccentric screed allows you to fasten the elements at different angles, assemble and disassemble the product several times. Furniture assembled using such an element is incredibly durable.

Scope of application

Furniture fasteners are used for L-shaped and T-shaped joints. Minifixes are in demand when assembling cabinets, tables, chests of drawers. They connect the covers and bottoms of cabinets, as well as countertops of computer and dining tables, cabinets and chests of drawers. In addition, with the help of eccentric couplers for furniture, they fasten parts where there is no way to drill holes. For horizontal elements, such as shelves, it is more convenient to use plastic ties. Bulky structures are assembled using reinforced eccentrics. Such fasteners are placed in the housing and contain an additional twilight.

The furniture is connected in such a way that the minifixes remain almost invisible. They can only be seen from the inside of the product. This moment can be considered the advantage of this type of fixtures, as they do not spoil the appearance of the furniture. An eccentric screed makes assembly of products simple, quick, and additionally gives rigidity to the entire structure.

Materials and equipment

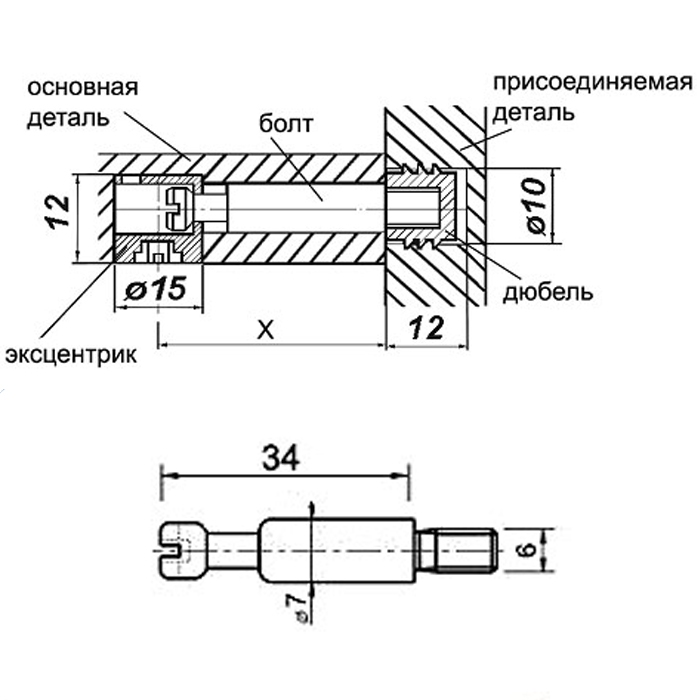

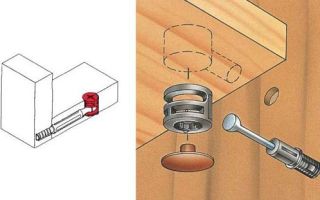

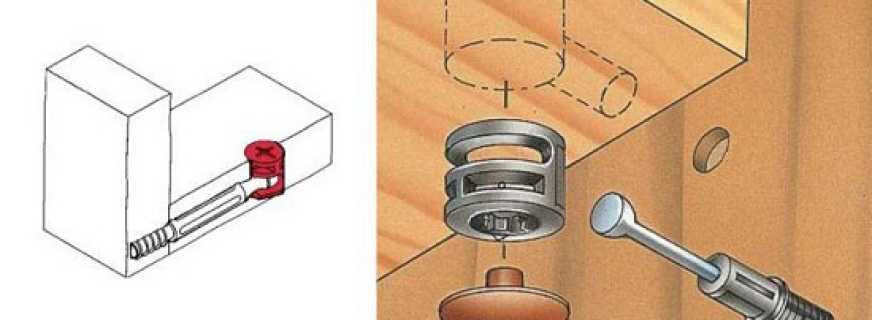

The eccentric screed consists of 3 elements: a stand, an eccentric and a nut acting as a foot. There are several types of fasteners that can be divided into groups depending on the material of their manufacture, rack length, diameter, size, type of fastening of the self-tapping screw and foot.

If you often disassemble and assemble furniture, this type of fastener will be the best option. It is ideal for products from chipboard and chipboard.

The eccentric coupler furniture is metal or plastic. The material depends on the scope of the interior. For example, when assembling kitchen sets, metal mounts are used, and plastic ones are suitable for small items. Racks can be short up to 38 mm and long - up to 58 mm. There are minifixes with a diameter of 12, 15 and 25 mm. Parts with a diameter of 15 mm are the most common. For the last, largest, special plugs made of polymer material are provided. The dimensions of the screeds are as follows: 5x50, 7x50, 7x70 mm. This allows you to use them when assembling almost any type of furniture.

Unlike self-tapping screws, eccentrics allow you to fasten elements at different angles. Most often, screeds are used to connect parts under 90, 135, 180 degrees. Depending on the type of connection, the types of fastening are as follows: self-tapping screw and screw. Manufacturers produce fasteners of different configurations.The composition may include:

- Eccentric;

- Futorka;

- Stock;

- Sleeve, dowel;

- Stub.

Installation Rules

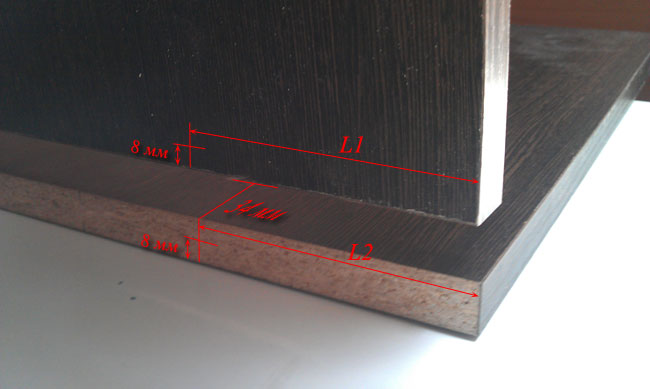

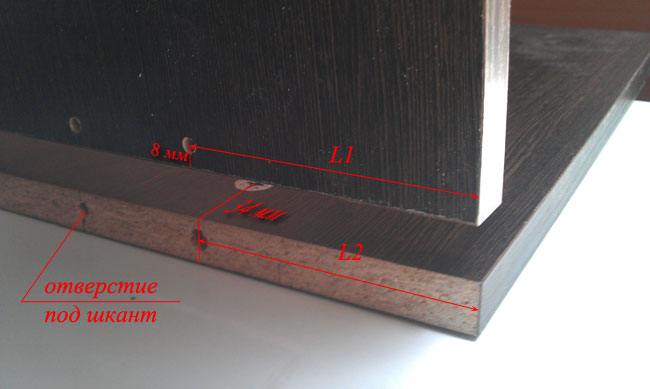

Before you begin, you need to figure out how to install the mounts. In the elements to be connected, 3 holes must be made. To do this, you need equipment for installation:

- Screwdriver;

- Frazer Forstner;

- Drill;

- Screwdriver.

Self-assembly of furniture parts by an eccentric is extremely rare. This is due to the difficulty of drilling holes. It is especially difficult to do that which is reserved for an eccentric. It does not have to be through, so a special Forstner drill is required. For standard mounting, its diameter is 15 mm. In order not to drill more than necessary, it is recommended to use depth gauges during drilling.

After, at the end of the same element, a passage for the rod is drilled. The foot is installed in another part. Both elements are interconnected. For more detailed instructions, see the video on installing the cam. For self-assembly of the product, you must carefully study the instructions that accompany it and familiarize yourself with the video materials. They are easy to find on the Internet. Thus, the assembled furniture will be provided with reliable fixtures and will last a long time.

Video