How to make a bar stool yourself, expert advice

Recently, handmade items have become increasingly popular. They give the room an individuality and can fully characterize its owner. The kitchen furniture created by its own design looks original. For example, making a bar stool with your own hands is not so difficult. Such a hobby can become not only a full-fledged hobby, but also a good income.

Content

Design and construction choice

Having opened any catalog of bar furniture, it is simply unrealistic to suddenly stop looking at a specific model, because the variety of shapes and colors is amazing. However, it is not always possible to find something suitable for your interior. In this case, it is worth making the furniture yourself. At production of bar stools it is necessary to consider a number of important parameters.

Properly calculated chair height is the key to convenience. The optimal distance from the seat to the bar counter is 25-30 centimeters. The presence of such a space provides comfort and freedom of movement.

A large surface area of the furniture contributes to relaxation, immersion in the atmosphere of comfort. However, not every bar table can allow a wide scope. Thinking about how to make a chair yourself, you need to calculate the size of the seat based on the width and depth of the countertop. It is advisable that during operation there should be no interference within a radius of 20 centimeters. This will provide comfort without violating the personal space of a person sitting at the bar.

When developing the design of the chair, it is necessary to consider the following components:

- Base. Of course, everyone has different preferences, but experts recommend the use of four legs. They will give the bar stool maximum stability and reliability. It would be useful to think about the possibility of adjusting the height, provided that among family members, relatives, acquaintances there are people of different stature.

- Back. For snacks or other short-term use of the chair, this parameter is not particularly important. If you plan to sit for a long period of time, then it would be wise to opt for a high, well-fixed back, which you can lean back at any time.

- Armrests. This design element is voluntary. There are no specific recommendations. It all depends on personal preference.

- Upholstery. Its presence is due to the prioritization between style and comfort. Rigid chair seats made of metal, acrylic, plastic, wood look more stylish, blending in perfectly with the modern interior.Soft models, covered with fabric or leather, are pleasant to the touch, more comfortable.

The deciding factor in the choice of design is the overall interior of the room. Traditional furniture, for example, would not be appropriate to look in a room decorated in the styles of hi-tech, bionics or brutalism. Do-it-yourself bar stool should harmoniously fit into the design of the room, not get out of the picture.

The color of the furniture is best chosen based on the overall color scheme of the room. This is especially important for the foundation. But as for the seat of the chair, it is recommended to give free rein to imagination. You can choose from a plain design to floral or animal prints. Then the bar stool will become a bright highlight in the interior.

What materials can be made

The base is a kind of foundation for the entire product, which takes on the main load, is responsible for reliability and stability. Therefore, if among those who will sit on a bar stool, there are people with a weight exceeding 90 kilograms, preference should be given to more durable materials. These include wood, metal. The latter looks very expensive, solid, but gives the product significant weight.

If a decision is made not to use upholstery for a seat, then this structural element can be made of natural wood. This noble material will give the bar stool the look of expensive, status furniture. Its disadvantage is its high cost. Use of plastic is allowed. Particular attention should be paid to the transparent version. It is appropriate when creating an atmosphere of lightness and airiness. However, one should not forget that this material is not durable and, as a result, can crack during prolonged use.

If you decide to make the seat softer, more comfortable, you can choose textiles or leather as upholstery. Natural materials are more suitable for the classic execution of a bar stool. Artificial ones are best used when creating high-tech products and the like.

You can make a bar stool yourself from one material or combine several options. This will give charm to the details of the interior, will make it possible to realize any fantasy. In addition, such a design will positively affect the final cost and functionality of the product.

Necessary tools

In order to make bar stools with your own hands, you must have a certain set of tools in the arsenal. Most devices are universal, but there are those that can only be used when working with wood or metal. If they are not available, you can rent.

|

Tool |

Destination |

Ability to use for wood |

Possibility of use for metal |

|

Pencil |

Marking |

+ |

+ |

|

Screwdriver |

Screwing in and out screwed parts |

+ |

+ |

|

Roulette |

Accurate measurements |

+ |

+ |

|

Square |

Building angles of 30 °, 45 °, 60 ° |

+ |

+ |

|

Chisel |

Sampling recesses, cleaning grooves, creating a drawing |

+ |

— |

|

Hacksaw |

Blank cutting |

+ |

+ |

|

Sandpaper |

Product Processing |

+ |

+ |

|

Fasteners |

Connection of parts |

+ |

+ |

|

Drill with drills with a diameter of 3 mm and 6 mm |

Making holes |

+ |

+ |

|

Glue |

Bonding materials |

+ |

— |

|

Electric jigsaw |

Sawing materials, creating curved cuts |

+ |

+ |

|

Bit |

Hollowing holes |

+ |

+ |

|

Hammer |

Shock work |

+ |

+ |

|

Screwdriver |

Twisting and unscrewing the connecting elements, drilling holes |

+ |

+ |

|

Plane |

Fitting parts |

+ |

— |

|

Solvent |

Giving paint fluids the desired consistency |

+ |

+ |

|

Stain |

Surface painting |

+ |

— |

|

Lacquer |

Glossy coating of the outer sides of the product |

+ |

+ |

|

Brushes |

Application of coloring components |

+ |

+ |

At first glance, it may seem that there is too much equipment and materials.But experienced craftsmen know that it is better to have extra equipment in your arsenal than at the right time, during the creative process, to interrupt and run to the construction department, for example, with the necessary drills or a plane.

Dimensions and drawing

Before starting the manufacture of a bar stool, you need to arm yourself with his drawing. This will allow you to determine the list of necessary tools, accurately calculate the amount of material and avoid errors in the work. The easiest and fastest way is to download the finished version. But since no one can give a 100% guarantee for the accuracy of the information, it is necessary to play it safe and personally check all the indicated dimensions.

The next option is to draw the future bar stool yourself, using special computer programs. This process takes more time, but gives a guarantee of creating a unique product of its kind. If there is no possibility or computer skills, then drawings can be sketched out manually. To do this, you need only a sheet of paper, a pencil, a ruler and a great imagination.

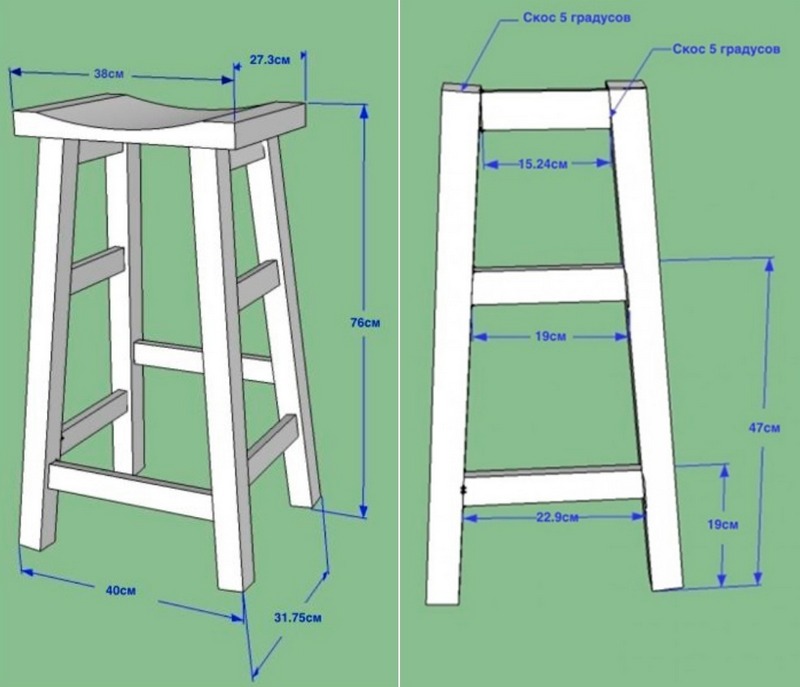

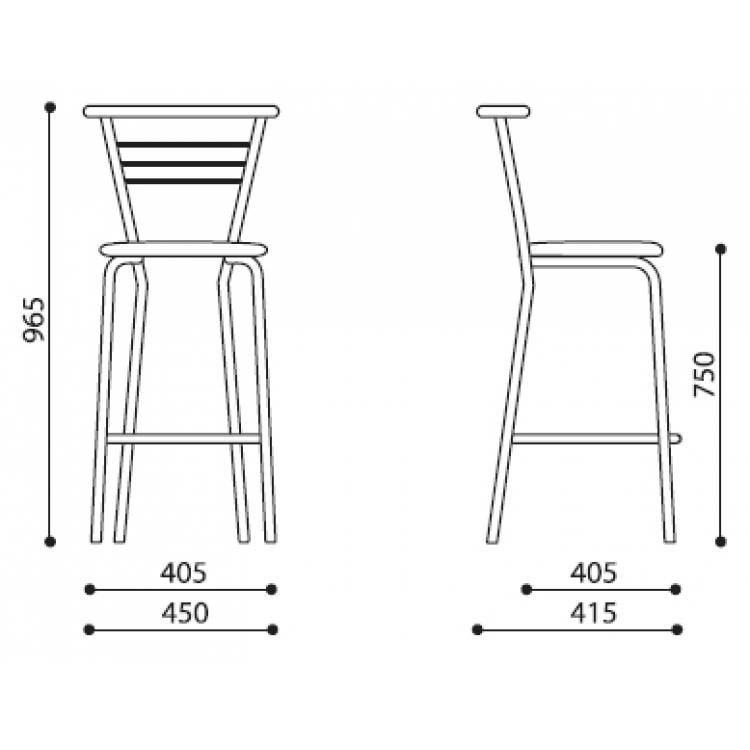

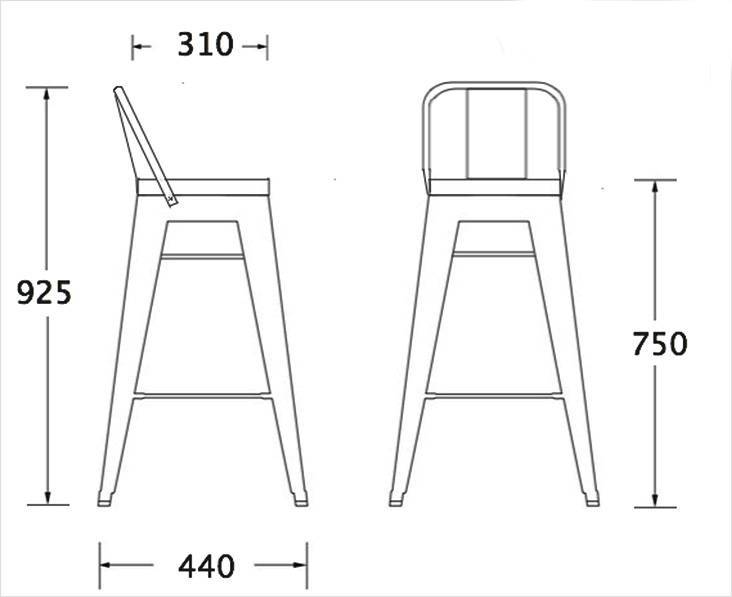

How the drawing appears does not matter. The most important thing is the right size. The quality production of a bar stool depends on them. It is necessary to accurately measure and put on the drawing the following dimensions:

- the height of the product from the floor to the seat (equal to the distance to the countertop minus 25-30 cm); standard - about 75-85 cm;

- the height of the back (if any) is about 20 cm;

- the length and width of the seat is at least 35 cm;

- the distance between the legs at floor level is approximately 44 cm.

The above standard sizes may vary according to individual preferences and dimensions of the bar. A folding chair with adjustable backrest and sliding legs will look interesting. For him, the drawing takes into account all the parameters in the retractable state.

DIY making

A bar stool can be made with your own hands from wood in the form of a stool or with a soft seat and back, as well as from plywood and metal. When working with the latest material from the master requires certain skills in welding. Therefore, they most often use a profile pipe, for which special knowledge is not needed.

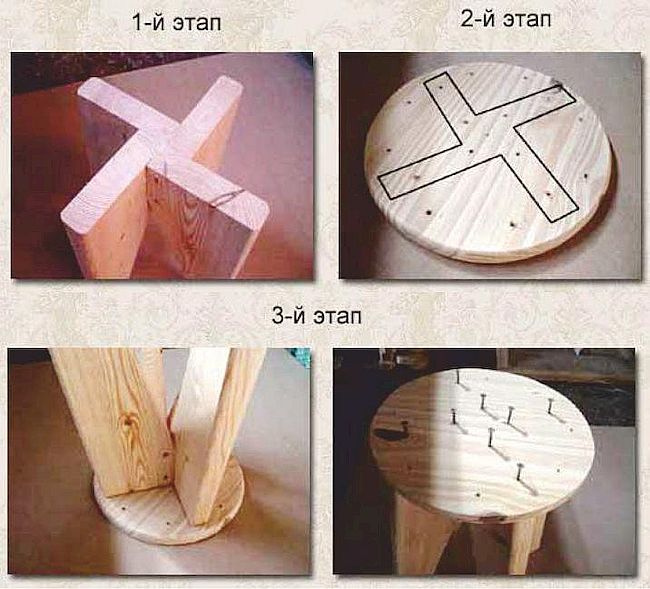

Wooden stool

Wooden furniture harmoniously fits into many interiors. It creates an indescribable atmosphere of coziness, comfort and warmth. A self-made chair will bring both aesthetic joy and practical benefits. It is recommended that the beginner try to create a simple wooden stool first, following the steps:

- Acquisition of wood. The most affordable materials are pine and birch. It is better to purchase shields with a thickness of 20-30 mm. If there is old, unnecessary wooden furniture, then you can use it.

- Drawing a marking on the material according to the drawing with a pencil.

- Cutting parts with a jigsaw. One circle is the seat itself with a diameter of 36 cm and a thickness of 3 cm, the second is a substrate under it with a diameter of 26 cm and a thickness of 2 cm. Four legs 3 cm thick (vertical wood structure), four stiffeners (footrest) 3 cm thick are also needed. Legs are recommended to be planed along the entire length, reducing the thickness down to 2.5 cm.

- Assembly of a chair. Using a screwdriver or screwdriver with 5 x 80 screws, the legs are connected to each other and with a small circle, with a 5 x 40 screw, the seat is screwed to a small circle, 5 x 20 screws are attached to the supports by means of the corners of the stiffeners.

- Grinding the entire chair with sandpaper.

- Coating the product with stain or varnish with a brush.

- The wooden stool is ready.

The undoubted advantages of wooden products are durability and aesthetics. But you need to take into account such a moment: in contact with water or with increased humidity in the room, the product can quickly become unusable, swell.

Wooden with padded seat and back

Having trained on a bar stool in the form of a stool, you can proceed to create a wooden model with a soft seat and back. Such a product is more comfortable and aesthetic. Below is a step-by-step instruction for the manufacture and fastening of parts and a description of the process:

- Materials for the chair are purchased.

- Markings are applied to wood.

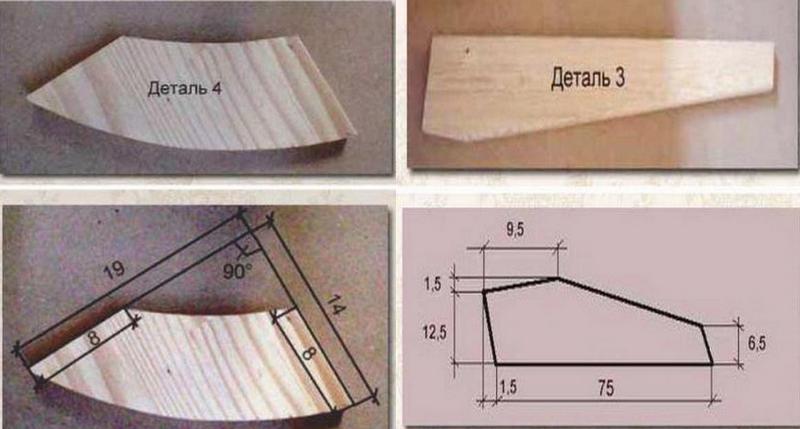

- Wood parts are made. Of the tools you need a jigsaw and chisel. Parts with the following dimensions will also be required: seat 34 x 34 x 2.5 cm, two front legs 2 x 44 x 74 cm, two rear legs 2 x 44 x 99 cm, front drawer 2 x 44 x 27.2 cm, rear drawer 2 x 44 x 32 cm, two lateral connecting strips 2 x 44 x 29.6 cm, two cuts of 1.5 x 22 cm each, four side cuts of 15 x 29.6 cm, two crossbars for the back 2 x 44 x 38 cm .

- The front part of the chair seat is trimmed in an arc, cleaned with sandpaper. On the other hand, nests 2 x 2 cm in size are knocked out with a chisel.

- Spikes are made with a hacksaw on all the drawers, two blind holes of 0.8 cm are drilled on the side with a drill.

- In the legs, nests are created for the spikes of the connecting strips according to the drawing. In the rear elements, a place is prepared for the back. Using a chisel, the upper part of 2 x 2.5 cm is removed.

- All parts are carefully sanded with sandpaper.

- Then you need to assemble the chair with a screwdriver, drill and screws.

- Paintwork is being carried out.

The following elements are required to create a soft seat:

- furniture foam or batting as a backing;

- Upholstery: natural or artificial leather, textiles;

- stapler and adhesive for furniture.

Adhesive is applied to the top and sides of the seat, the edges of the filler and the edge of the upholstery and held for about 3-4 minutes. Then the substrate is pressed tightly to the base and is covered with upholstery material, which is fixed with a furniture stapler. After that, the seat is mounted on an already made, painted chair frame.

From a profile pipe

Recently, metal pipes have become widespread in the manufacture of furniture. Master classes with their use are recommended for beginners. From the profile pipe, the chair body itself is made. Therefore, it is better to give preference to stainless steel, because products from it are characterized by strength and durability. How to make a bar stool with your own hands from pipes - this is the next master class. Follow the instructions below:

- Stock up with the required material and tools: foam rubber, upholstery, metal pipes, fasteners, chipboard or plywood, pipe benders, drill, screwdriver or screwdriver, construction stapler.

- In accordance with the drawing, cut blanks from a metal profile. After that, give the upper part of the pipes a semicircular shape using a pipe bender.

- Connect the bent parts together using fasteners using a screwdriver or screwdriver.

- Seat cut out of plywood or particleboard. The shape can be either round or square. To give softness, apply foam, cover with a cloth and fix all this on the underside with a stapler.

- Connect the two parts of the structure using bolts.

- From below, plastic or rubber plugs should be inserted into the metal pipes. This will protect the floor from scratches.

The chair made of pipes fits perfectly into the interior created in the high-tech style. While playing in contrast to a classic kitchen, it will add a relaxed atmosphere to the bar, while in a minimalist one it will be in perfect harmony with the design of the room.

From plywood

Quite easy to use material is plywood. Unlike wood, it is more moisture resistant and reliable. The instruction for creating such a model is similar to making a bar stool from wood:

- in accordance with the drawing, marking is applied to plywood, then using a jigsaw, workpieces of parts (legs and seat) are cut, which are subsequently sanded with sandpaper;

- holes for hinges are created on the parts with a drill, hollows are hollowed out with a chisel;

- all components are assembled in one design;

- the chair is covered with varnish or paint.

The most optimal option when creating a bar stool will be the use of coniferous plywood. This material is wear-resistant, retains an attractive appearance for a long time, is less susceptible to the spread of fungi and the appearance of bugs. In addition, the first time products from coniferous plywood will exude a pleasant aroma.

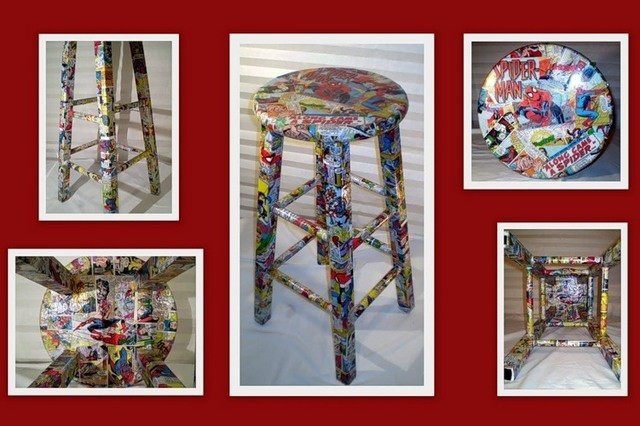

Decoration Methods

To add personality to a bar stool, it can be decorated in various ways. Due to the variety of colors and prints, the seat upholstery made of leather or textile (jacquard, microfiber, silk) will make the furniture a bright element of the interior. Covers will be a great solution for those who do not want to engage in close-fitting. They are practical, they can be replaced at any time.

Decoupage is gaining more and more popularity when decorating furniture. It is used when working with wood as follows: the surface is cleaned with sandpaper, painted with putty and painted, then decorations from napkins and flower pictures are pasted. In conclusion, the product is varnished.

If creative abilities are not sufficiently developed or there is simply no time, then you can decorate the chair with bright colors, which will also give it uniqueness. An interesting solution will be the use of jute rope - it can wrap structural elements with it. The choice of decorating methods is huge. It all depends on tastes, desires, abilities, imagination. Be that as it may, a bar stool, made and decorated with your own hands, will become the highlight of any interior, the pride of the master.