Do-it-yourself options for making a chair, diagrams and drawings

At home, I want to relax in a comfortable environment, feeling cosiness around me. A mandatory attribute for its creation is upholstered furniture. Sofas and armchairs that are not always presented in stores suit design or quality, not to mention current prices. As an option, you can make a chair with your own hands, which is guaranteed to meet all individual preferences. Sizes, tone of upholstery and softness level - you can choose everything to your liking, resulting in a designer interior item.

Content

Preparatory stage

Before starting work on assembling the chair at home, you need to decide on the main parameters of the future product. You should start with the appearance. In accordance with the style of the room where the upholstered furniture will be installed, a suitable model is selected.

It is advisable to study the range of finished products in the exhibition halls or see photos in catalogs. In the first case, you can clearly see and touch the planned model, but it will take some time to search. In the second case, the time costs will be minimal, but the final appearance may differ significantly from the desired one.

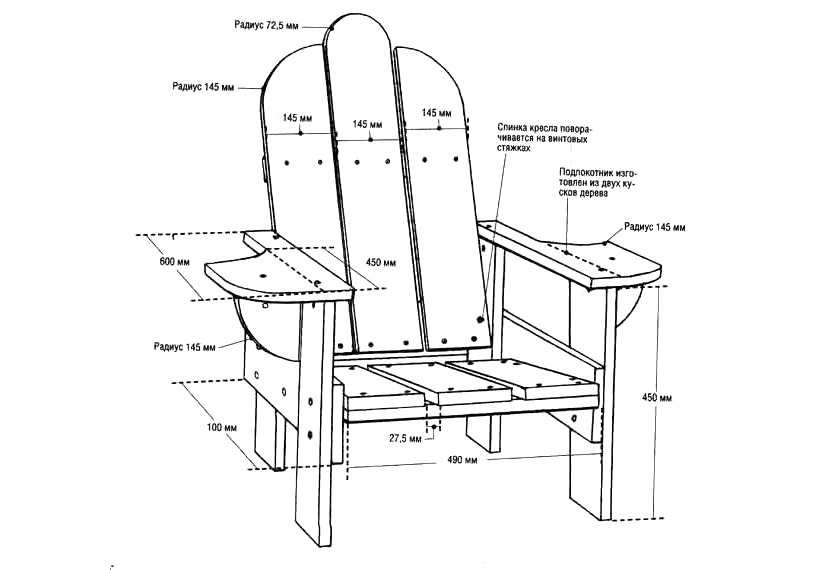

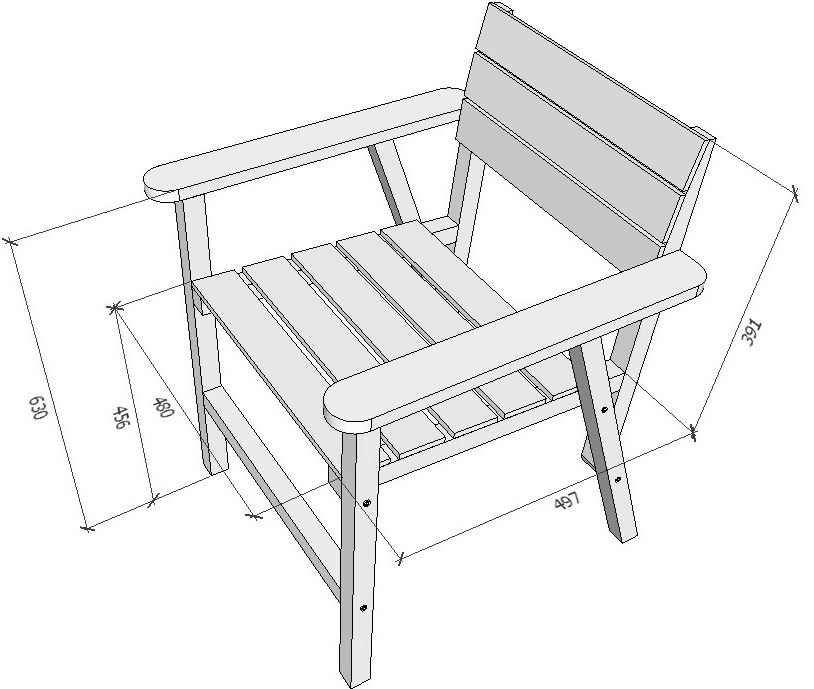

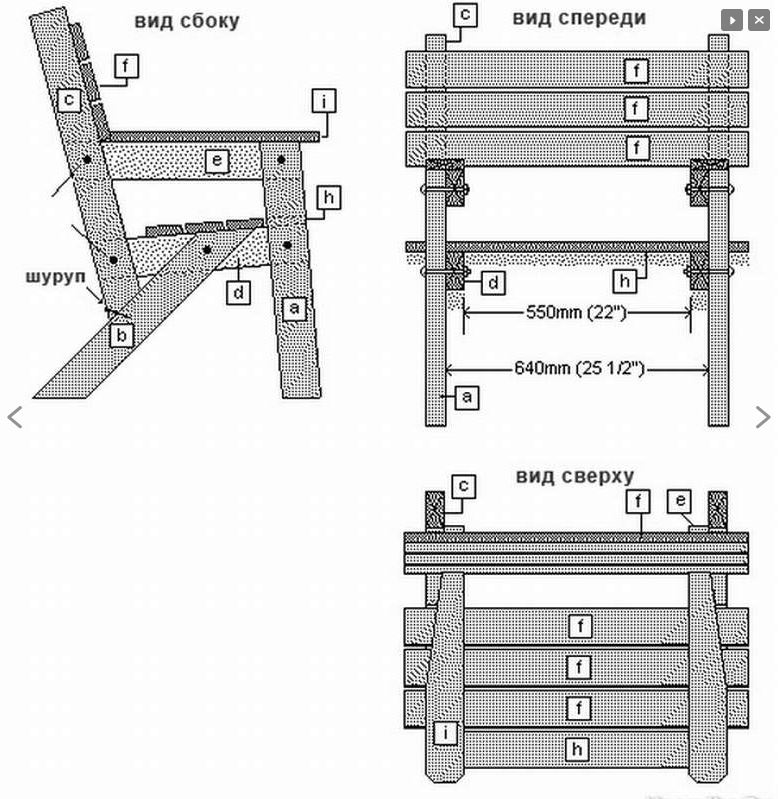

Having studied the assortment of chairs and having decided on the model, you can begin the preparatory work. To begin with, it is worth measuring the place where you plan to put the furniture, and calculate the dimensions. In order to avoid mistakes in fitting parts and not to forget anything, competent drawings and diagrams are compiled.

The generally accepted ergonomic seat height is approximately 45 cm, its width and depth vary from 40 to 45 cm. The height of the backrest from the floor should be about 1 meter. For the convenience of sitting, a 3 cm slope is made from the edge to the back.

To make a drawing of a chair on a sheet of graph paper or checkered paper, a completely finished model is initially drawn, and then separately depicted:

- back;

- side part;

- seat;

- the armrests.

When schematically modeling, it is necessary to take into account the thickness of the material from which the chair will be made. Synthetic and natural fabrics have different parameters, which can affect the final collection of parts. After completing the drawing, it is advisable to draw the parts templates on cardboard and cut them out. This will make it possible to try on dimensions in full size and project the necessary elements on the material.

Before purchasing, a complete calculation of the amount of required materials is mandatory. This is done in order to exclude a repeated trip to the store and the acquisition of excess parts.

For components, you can go to the construction market or to a specialized store.You can also order materials with delivery, but in this case there will be no way to visually evaluate their appearance and quality.

Materials and Tools

The frame is an important part for any furniture. To properly make a chair, you should decide on the material in advance. Most commonly used:

- tree;

- Chipboard, chipboard;

- plywood;

- metal.

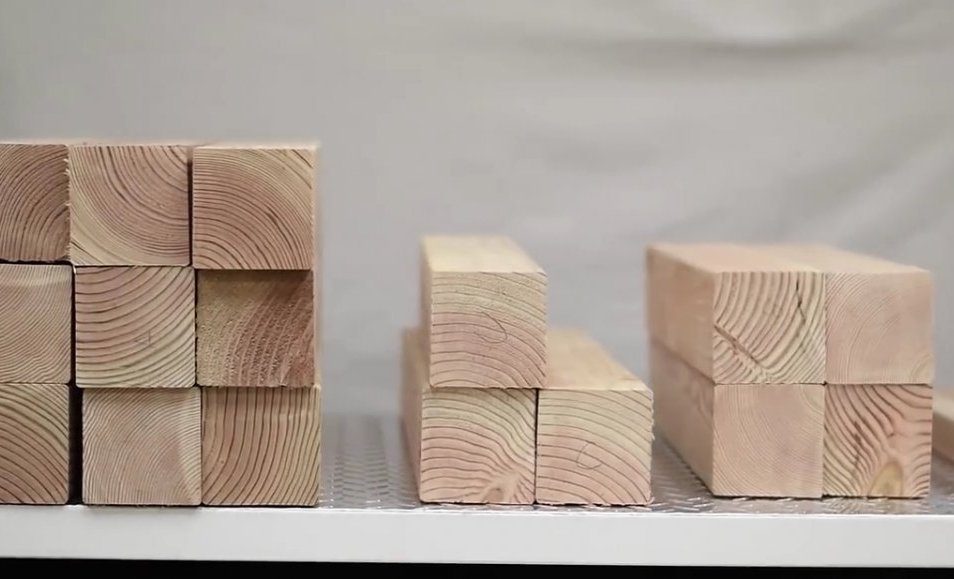

Wooden frames are the most environmentally friendly, do not cause allergies. A chair made of boards will last a long time if the wood is of good quality and is selected correctly. You should not take lumber with the presence of bark, cracks, as well as having fuzzy geometry - all this will lead to cracking and deformation of the finished product.

A homemade chair with a frame made of chipboard is durable if the material is of sufficient density, thickness, dry and does not crumble. Unlike wood, synthetic material cannot be painted, the surface can be given the desired texture and tone.

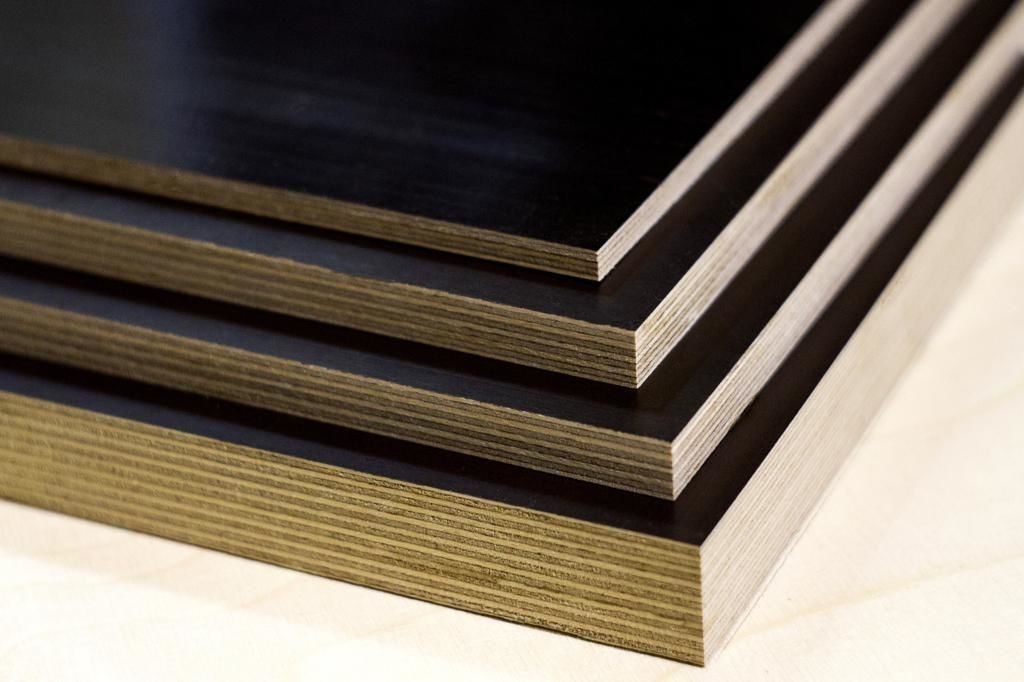

Plywood is also used to make the frame of a home chair. Due to the low attractiveness of the texture of the material, it is covered with soft upholstery. With proper bonding, plywood thickness of 15 mm and above, the part can be operated for a long time.

Laminated plywood has appeared on the building materials market with an attractive appearance. It can be used for open parts of the chair without loss of visual effect.

A self-mounted metal frame of the chair will be the most durable, but its weight will significantly exceed other options. The disadvantage is that you can only make it if you have specialized welding tools. You can fasten metal parts with nuts and bolts, but over time, such a frame will begin to loosen and rattle.

Regardless of what material the frame for the chair will be made with your own hands, this part is the main one and must be assembled efficiently and firmly.

A dense furniture fabric is prepared for upholstery. The most common options are:

- shenill;

- tapestry;

- jacquard;

- velours;

- flock;

- synthetic or genuine leather.

The choice of material is made taking into account future operating conditions. So, if there are pets or children who, due to age, can damage or stain the fabric, it is better to give preference to easy-to-care, wear-resistant materials. Parts should be cut with allowances for seams, so the material should be purchased with a small margin.

Soft elements are filled with furniture foam with a density of 30 and above. You can make upholstery from improvised materials, for example, instead of foam rubber, use old blankets or pillows.

To make a chair with your own hands you will need:

- screwdriver or welding machine;

- jigsaw with the necessary nozzles or a saw-grinder;

- furniture stapler;

- sewing machine;

- scissors;

- a chalk or piece of dry soap;

- Sander;

- hardware for fixing parts.

All tools, as well as accessories should be prepared before the installation process, so as not to waste time searching for the necessary elements.

Model-specific manufacturing steps

The process of making a chair with your own hands directly depends on the chosen model. Homemade products may not even be inferior in comfort and appearance to factory counterparts.

Traditional

A traditional armchair is an excellent design solution for creating a comfortable atmosphere in the house. Unlike sofas, chairs take up much less space, and making them yourself with wood, chipboard or metal is faster and easier.

After preparing the tools, a site for assembly is selected. It is advisable that no one moves the decomposed materials. It is important to consider the side effects of the manufacturing process and their consequences for others.When sawing wood with a jigsaw, sawdust should not fall on furniture and interior items, and when using inverter welding, it is necessary to adhere to fire safety requirements. When all preparations are completed, you can begin to begin installation.

Work Stages:

- using templates from cardboard, transfer the mock-up of parts to frame materials;

- use a jigsaw or grinder to cut elements along the lines of the drawing;

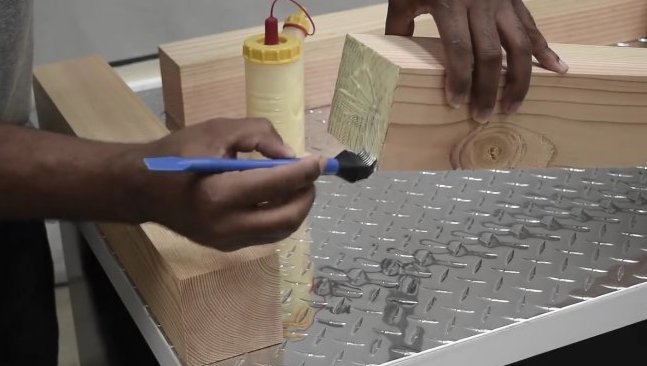

- open parts from bars, if necessary, process with a grinder;

- fasten the frame parts with a screwdriver or using a welding machine;

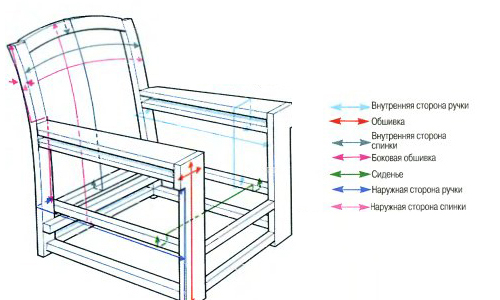

- draw upholstery pattern on furniture fabric, cut with allowances for seams 1 cm, sew details;

- cut and cut furniture foam, fill the upholstery;

- the armrests are wrapped with foam and fixed with a special stapler. Decorative wooden armrests, if necessary, are fixed on top with a screwdriver and self-tapping screws.

If the wooden chair will be in a room with high humidity, after assembling the frame it should be treated with bioprotective agents.

After completing installation work, you can decorate the chair to your liking. Small buttons are tightened with furniture fabric, which are sewn to the product in a checkerboard pattern. By applying paints of different colors and sanding, wooden elements are decorated with antique do it yourself.

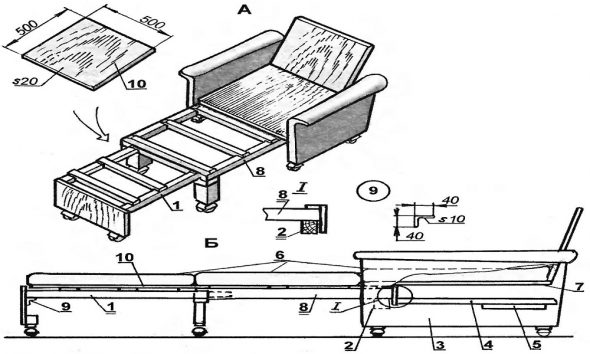

Folding

A folding chair is a great way to organize a place to relax. Such an element of furniture, made for use in garden areas, is indispensable in the summer. A do-it-yourself garden chair will fulfill its functional purpose to the full and will not yield to factory analogues. The possibilities of using a folding piece of furniture make it possible to use it in the most unexpected situations: guests staying overnight, moving, relaxing on the veranda. Wooden chair is made in a variety of styles. Having chosen the design, having completed the drawing, you can begin assembly work:

- cut the prepared materials with a jigsaw or grinder to the desired size;

- treat the surface with a grinder to give smoothness, otherwise it is possible to separate sharp traumatic particles;

- treat with bioprotective agents and dry well;

- paint all the details in the right color;

- assemble the chair frame with a screwdriver, screws and the necessary fasteners.

Wooden chairs are decorated for almost any style. For processing, varnishes, paints and patinating enamels are used.

The finished chair is definitely worth checking for strength. With the correct implementation of all points, a folding armchair made of timber will last a long time.

From pallet

Building pallets are assembled from flat boards that have dried and will no longer change geometry. Nevertheless, their use as a material for the independent manufacture of chairs is widespread. Original models in the loft style are obtained from pallets, which almost do not differ from design options. Production includes several stages:

- After choosing a model and preparing using a grinding machine, the boards are sanded. Without this process, delamination of wood is possible.

- Using a jigsaw or grinder, pallets are cut in half, the edges are sanded and painted over.

- From the elements you need to assemble a frame chair from the boards of the desired shape, and then fix the elements with screws and a screwdriver.

Such a DIY chair for a summer residence looks no worse than store analogues. For comfortable use of the seats from the pallets, it is necessary to sew pillows on them. The fabric is selected based on the operating conditions of the furniture. As a filler, you can use foam rubber, holofiber, synthetic winterizer, polystyrene foam balls.

Useful Tips

Making furniture items yourself is a very exciting experience. If the process is the first time, make the most uncomplicated chair with clear lines and simple geometry. It will be easier to work, and the result will be neat.

When there is experience in the carpentry, you can surprise family and friends with unusual forms. Do-it-yourself round armchair is effective and practical in any interior. Another simple way is to make a chair out of the car seat left in the garage.

By being creative, following the instructions, you can make a chair with your own hands, which will be used for its intended purpose for many years. In addition, a self-made product will be the pride of the owners and an occasion to brag to friends.

Video