Making DIY TV stands, all the nuances

Modern interior items with high quality and attractive appearance have a high cost, so not every buyer can afford such expenses. Also, an unusual and unique style is often formed in the living room, for which it is difficult to choose a finished structure. In this case, a cabinet can be created under the TV with your own hands, because the future owner completely controls this process, therefore only environmentally friendly and safe materials will be used.

Content

Model selection

Before you make a TV stand with your own hands, you need to decide what size it will have, what shape it will have, what additional elements it will be equipped with. It is decided which material will be used in the process.

Most often, various interior items are created from drywall with your own hands, since this material is considered easy to process, it can make really unique and unique designs, and it also has an affordable price.

When creating a TV stand, wood is usually selected, since the design for a TV from plasterboard may not withstand the significant load of heavy equipment. If drywall is selected, then the frame must be well reinforced.

The most commonly selected materials are:

- the design for a plasterboard TV may have unusual forms, but needs to be carefully strengthened, and the ability to work with this material is also required;

- Particleboard is selected in the absence of significant funds that can be allocated for the planned work, and material is produced in numerous shades and is easy to process;

- MDF is considered an excellent choice for creating a bedside table on which it is planned to install a TV, since the material is environmentally friendly, durable, with a uniform structure and light weight;

- Natural wood is the best choice, since a wooden structure with your own hands turns out to be strong, durable, extremely beautiful and fits well into almost any interior style.

When it is decided what material will be used in the work, important questions should be decided:

- the shape of the cabinet depends on the preferences of the owners;

- the dimensions are determined depending on the installation location and the dimensions of the TV itself, and it is taken into account whether the design will be used not only for the installation of this equipment, but also for any other purposes, since if it is planned to store different small or large objects on it, it is desirable make it with special storage elements.

Before the immediate work, drawings and diagrams are certainly made, according to which all subsequent stages of the process will be further implemented, otherwise it is very likely that numerous errors will be made, which will be difficult to eliminate.

Materials and Tools

How to make a cabinet? To do this, it is important to initially pay attention to competent preparatory work. They are to perform the following actions:

- drawings are made of the future design, and if the future owner does not have the skills to work independently, then he can take advantage of simple and affordable programs available on the Internet;

- materials are being prepared, which include wood or chipboard and MDF boards, plywood, fasteners for fixing the parts together, plastic caps, putty of the optimum color, plastic edge, facades for the cabinet, stands, accessories and decorative elements for decoration;

- the tools that are needed during the work are being prepared, and an electric jigsaw, a screwdriver, a drill with different drills, a screwdriver and other tools for applying high-quality and correct marking are counted here.

Thus, a do-it-yourself bedside table for TVs can be made of fairly simple and affordable materials, and for this you do not need to purchase expensive and specific tools. Usually every man has all the necessary elements.

Cutting out the details

After completing all the preparatory steps, you can directly make a TV stand with your own hands. For this, the cutting of all the details of which this design will consist is initially implemented. The procedure is divided into successive stages:

- whatman is prepared, on which all the details required to create a high-quality and durable cabinet are applied;

- it is important during this work to use pre-formed drawings and diagrams, which will allow you to draw the correct patterns;

- the resulting patterns are superimposed on a particleboard cloth, after which they are fixed, for which it is recommended to use clamps;

- careful cutting of these parts begins, and for this it is necessary to use a high-quality electric jigsaw;

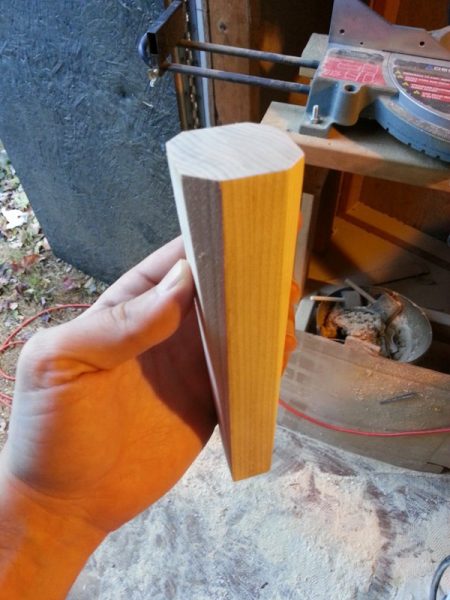

- grinding of all edges of the resulting workpieces is performed.

Often there are problems in the process of cutting parts, since not all people know how to handle a jigsaw correctly, therefore it is recommended to practice a little before this process, so that when creating parts there are no irregularities and ugly edges.Doing it yourself will depend on the proper cutting of the details of how a bedside table for a TV will look, and whether it can cope with the planned loads from large equipment.

Edging Elements

To make the ends of the cabinet itself look attractive and unique, it is recommended that all parts be edged before assembly. For this, it is considered optimal to use a special edge made of PVC or another material. PVC edging is considered inexpensive and easy to use, so the work is available even to beginners.

PVC edging can cut into or stick to the edges of existing parts, and the choice of method depends on the wishes and skills of the person involved in the construction.

A wooden pedestal can be turned over in different areas, but most often this process is carried out for those places where there is a high probability of damage during operation of the product. The entire process of edging parts is divided into stages:

- in the center of the end, the mill is correctly set;

- grinding of the faces of the parts is carried out, and it is important to ensure that chips or other problems do not appear, which are almost impossible to eliminate;

- various grooves are milled accurately;

- Further, the edging is carefully crammed, for which it is necessary to use a rubber mallet, and during operation it is necessary to ensure that impacts do not lead to a violation of the integrity of the parts;

- the ends of the edging are cut off from the ends, after which the elements are polished flush.

A design made with such a border will look really attractive and modern, so ugly and unprocessed areas will be completely absent.

Assembly

After preparing all the parts that are parts of the future design, this bedside table is assembled. To make the TV cabinets with your own hands really high-quality and reliable, the basic rules of this process are taken into account:

- all parts are connected. You can use different mounting methods for this. Most often, holes are drilled in different elements, after which dowels are used for a reliable connection. Another method involves the use of self-tapping screws designed to work with wood or special confirmations, and the caps of all fasteners should be deeply embedded into the material. So that they do not spoil the appearance of the structure, special decorative stickers are used. The third option for connecting parts involves the use of eccentrics, which are used everywhere in the manufacturing process of various furniture. The complexity of this method is that for working with eccentrics it is necessary to have the appropriate skills, since if the depth is not calculated correctly or the drilling is not too accurate, a through hole can be obtained;

- different shelves or doors are installed, if they are planned in such a bedside table. Their number may be different, so it is possible to make a bedside table containing the optimal number of different compartments. Their sizes depend on what exactly is planned to be stored here;

- assembly of boxes is in progress. They are usually made from the same material that was used to create the entire cabinet. The depth and other parameters of such boxes completely depend on what will be contained in them. The facade must certainly be well suited for the entire structure;

- the accessories are fixed, providing ease of use of different drawers or cabinets. For this, handles and guides are used, along which the boxes move.

Thus, the procedure for creating a cabinet on which the TV will be installed is a fairly simple and understandable process for which different materials and elements can be used.

Foot fixing

After creating the nightstand, the final processes are realized, consisting in simple actions:

- legs are installed, and they can be stationary and adjustable, and their number depends on the size and parameters of the cabinet;

- the structure is processed with sandpaper, and then covered with high-quality putty;

- after the coating has dried, it is cleaned with a sandpaper;

- the made interior item is painted with nitro-paint, for which you can choose different shades, and photos of the finished results are located below.

Thus, if it is not possible to purchase a TV stand or if it is difficult to find a suitable design for the existing interior style, then creating such an object is a simple and understandable job. It is easy to do with your own hands, for which different materials can be used. To get the perfect result, you must accurately follow the sequential steps of this process, and use only high-quality materials and tools.

Video